Volvo Photo Locations Part 364

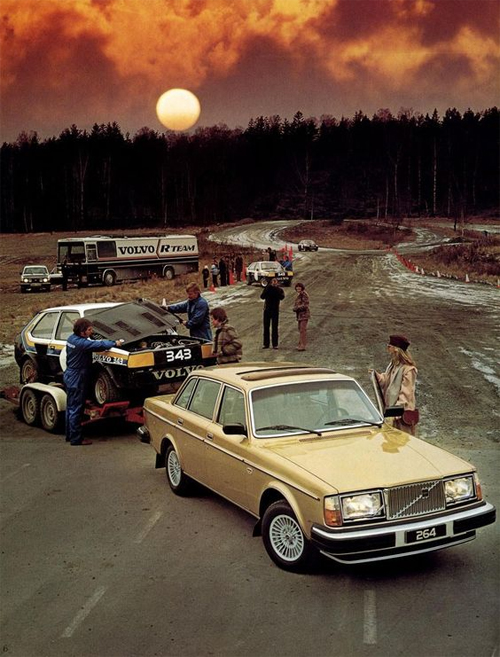

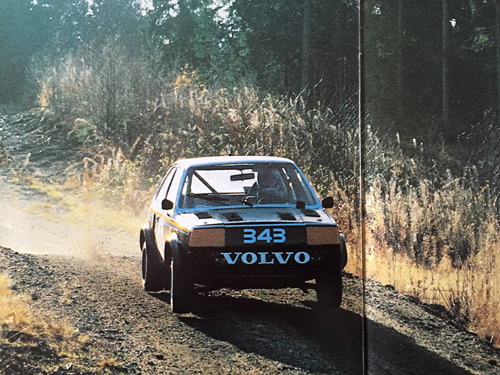

1979 – Volvo 264 GLE with Volvo 343 Rally at a Hällered Proving Ground or Volvo Cars Test Track in Sweden 🇸🇪. The Volvo R-Team bus is registered as FLO 950, and is today under renovation. The 1978 Volvo 245 was registered as DOR 740 and does no longer excist. At the 343 Rally car we see Jan Hansen, also known as Janne Dansken and Tony Garnemyr (right). Funfact to mention is that this 264 didn’t have a towingbar for the trailer with the 343 Rally, none of the rallycars here was able to drive. This photo was made at the end of 1978 by, probably Lennart Pettersson, who did many press photography those days. Thanks to Paul Malfroot from Jakobs Magazine for finding this location!

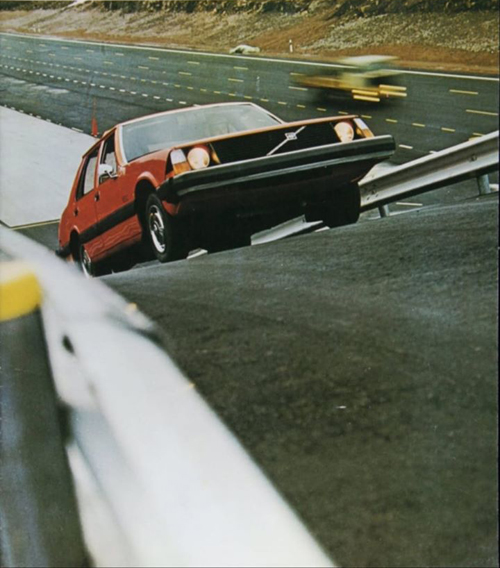

1972 – Volvo VESC at Volvo Hällered Proving Ground

1973 – Volvo VESC on Volvo Hällered Proving Ground

1973 – Volvo VESC on Volvo Hällered Proving Ground

1973 – Volvo VESC on Volvo Hällered Proving Ground

1973 – Volvo VESC at Volvo Hällered Proving Ground

1973 – Volvo VESC at Volvo Hällered Proving Ground

1973 – Volvo AB Product Range at Volvo Hällered Proving Ground

This photo was taken in May 1973 during the opening of the Hällered Proving Ground.

1973 – Volvo AB Product Range at Volvo Hällered Proving Ground

This photo was taken in May 1973 during the opening of the Hällered Proving Ground.

1973 – Volvo AB Product Range at Volvo Hällered Proving Ground

This photo was taken in May 1973 during the opening of the Hällered Proving Ground.

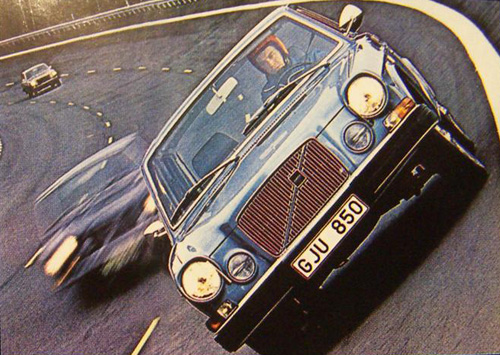

1974 – Volvo 144 Overdrive on Volvo Hällered Proving Grounds.

1974 – Volvo 144 on Hällered Proving Grounds.

1974 – Volvo 144 on Hällered Proving Grounds.

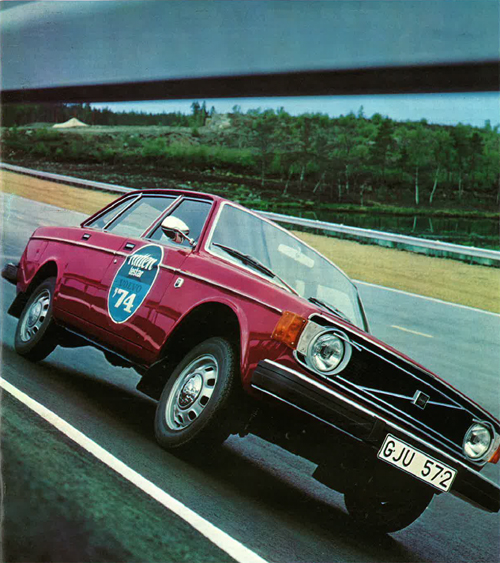

1974 – Volvo 142 GL at Volvo Hällered Proving Ground

1974 – Volvo 144 at Volvo Hällered Proving Ground

1974 – Volvo 144 at Volvo Hällered Proving Ground

1974 – Volvo 144 at Volvo Hällered Proving Ground

1974 – Volvo 144 at Volvo Hällered Proving Ground

1974 – Volvo 144 at Volvo Hällered Proving Ground

1974 – Volvo 144 (Japan) at Volvo Hällered Proving Ground

1974 – Volvo 144 (Sweden) at Volvo Hällered Proving Ground

1974 – Volvo 164E at Volvo Hällered Proving Ground

1974 – Volvo 164E at Volvo Hällered Proving Ground

1974 – Volvo 164E (USA) at Volvo Hällered Proving Ground

1974 – Volvo 164E at Volvo Hällered Proving Ground

1974 – Volvo 164E at Volvo Hällered Proving Ground

1975 – Volvo 245 DL on Volvo Hällered Proving Grounds

1975 – Volvo 244 (USA) at Volvo Hällered Proving Ground

1975 – Volvo 244 at Volvo Hällered Proving Ground

1975 – Volvo 244 (USA) at Volvo Hällered Proving Ground

1975 – Volvo 264 DL at Volvo Hällered Proving Ground

1975 – Volvo 244 DL at Volvo Hällered Proving Ground

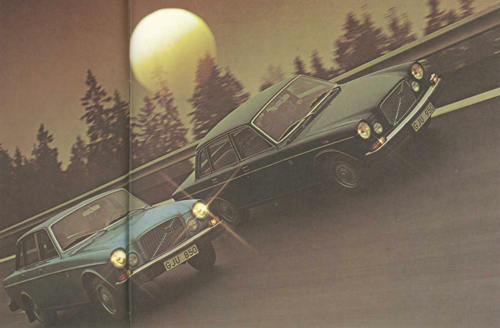

1975 – Volvo 244 DL and 264 GL at Volvo Hällered Proving Ground

1976 – Volvo 244 at Volvo Hällered Proving Ground

1977 – Volvo Elbil / Electric Car at Volvo Hällered Proving Ground

1977 – Volvo Elbil / Electric Car at Volvo Hällered Proving Ground

1977 – Volvo 244 DL at Volvo Hällered Proving Ground

1977 – Volvo 244 GL at Volvo Hällered Proving Ground

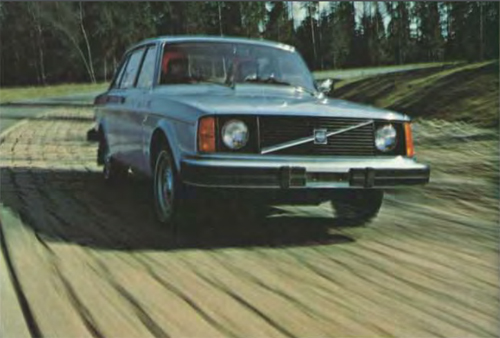

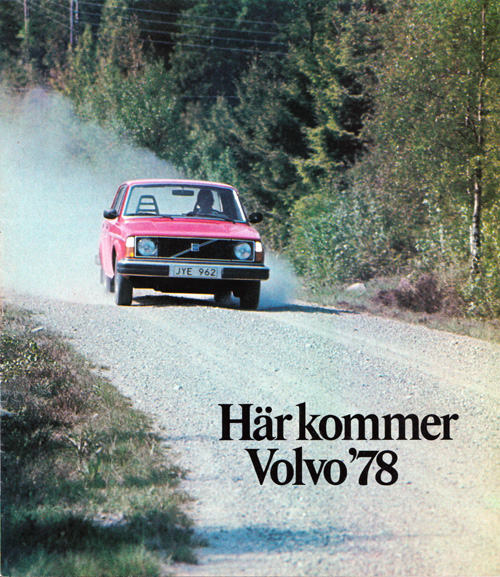

1978 – Volvo 244 DL at Volvo Hällered Proving Ground

1978 – Volvo 244 on Volvo Hällered Proving Ground

1978 – Volvo 244 DL at Volvo Hällered Proving Ground

1978 – Volvo 244 DL at Volvo Hällered Proving Ground

1978 – Volvo 244 DL at Volvo Hällered Proving Ground

1978 – Volvo 244 DL at Volvo Hällered Proving Ground

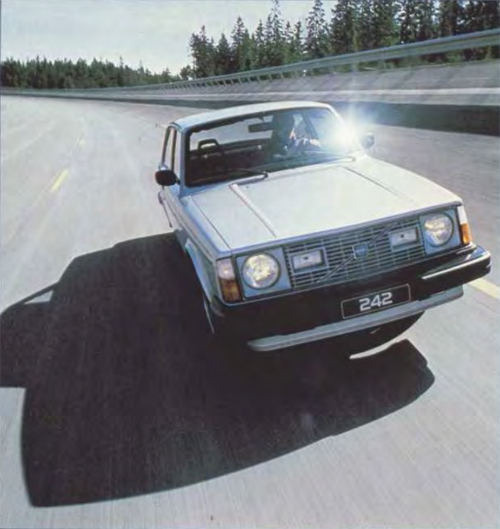

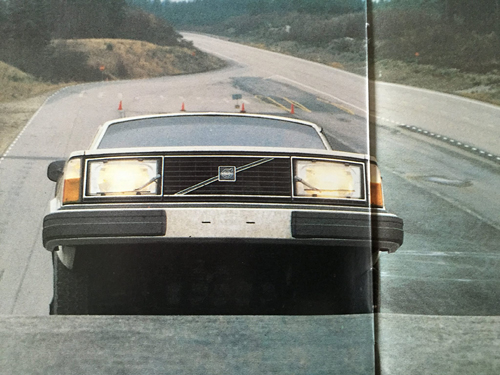

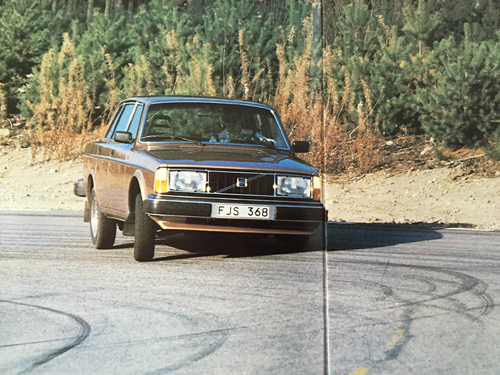

1978 – Volvo 242 GT at Volvo Hällered Proving Ground

1978 – Volvo 242 GT at Volvo Hällered Proving Ground

1978 – Volvo 242 GT at Volvo Hällered Proving Ground

1978 – Volvo 242 GT at Volvo Hällered Proving Ground

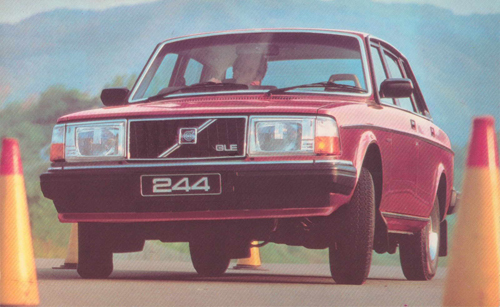

1979 – Volvo 244 DL at Volvo Hällered Proving Ground

1979 – Volvo 244 GL at Volvo Hällered Proving Ground

1979 – Volvo 244 GL at Volvo Hällered Proving Ground Sweden 🇸🇪

1979 – Volvo 245 GLE and 265 (UK) on Volvo Hällered Proving Ground

1979 – Volvo 245 and 265 on Volvo Hällered Proving Ground

1979 – Volvo 245 and 265 GL (USA) on Volvo Hällered Proving Ground

1979 – Volvo 244 GLE (Japan) at Volvo Hällered Proving Ground

1979 – Volvo 244 GLE at Hällered Proving Ground in Sandhult near Borås Sweden 🇸🇪

1979 – Volvo 244 GLE at Hällered Proving Ground in Sandhult near Borås Sweden 🇸🇪

1979 – Volvo 244 GL at Volvo Hällered Proving Ground

1979 – Volvo 244 GL at Volvo Hällered Proving Ground

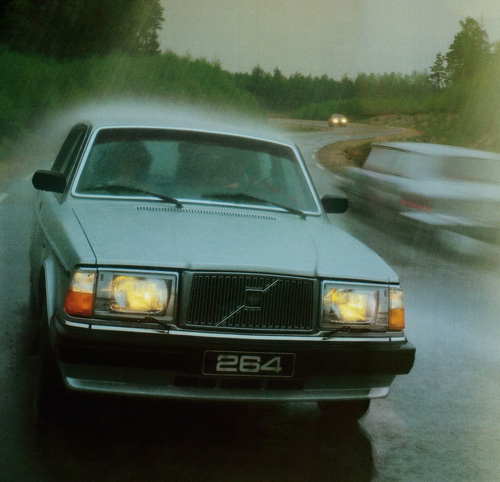

1979 – Volvo 264 GLE at Volvo Hällered Proving Ground

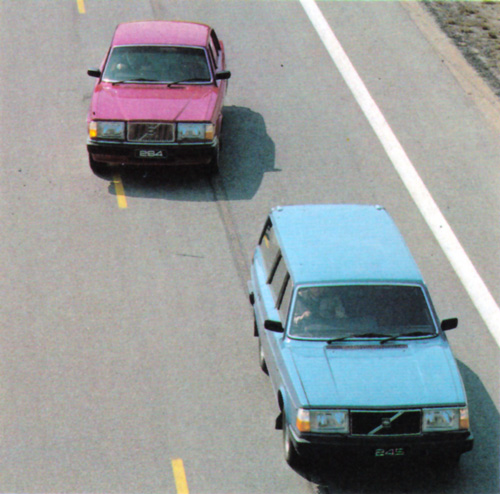

1979 – Volvo 244 DL, 264 GL and 245 DL at Volvo Hällered Proving Ground

1979 – Volvo 264 GL and 244 DL at Volvo Hällered Proving Ground

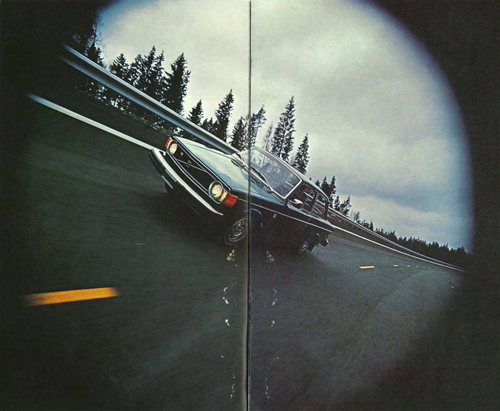

1979 – Volvo 264 on Volvo Hällered Proving Grounds

1979 – Volvo 244 DL at Volvo Hällered Proving Ground

1980 – Volvo 244 at Volvo Hällered Proving Ground

1980 – Volvo 244 GLE at Volvo Hällered Proving Ground

1980 – Volvo 244 GLE at Volvo Hällered Proving Ground

1980 – Volvo 244 GLE at Volvo Hällered Proving Ground

1980 – Volvo 242 DL at Volvo Hällered Proving Ground

1980 – Volvo 264 GLE at Volvo Hällered Proving Ground

1980 – Volvo 244 GL at Volvo Hällered Proving Ground

1980 – Volvo 244 GL at Volvo Hällered Proving Ground

1980 – Volvo 244 at Volvo Hällered Proving Ground

1980 – Volvo 244 GLE (UK) at Volvo Hällered Proving Ground

1980 – Volvo 343 Rallycross at Volvo Hällered Proving Ground

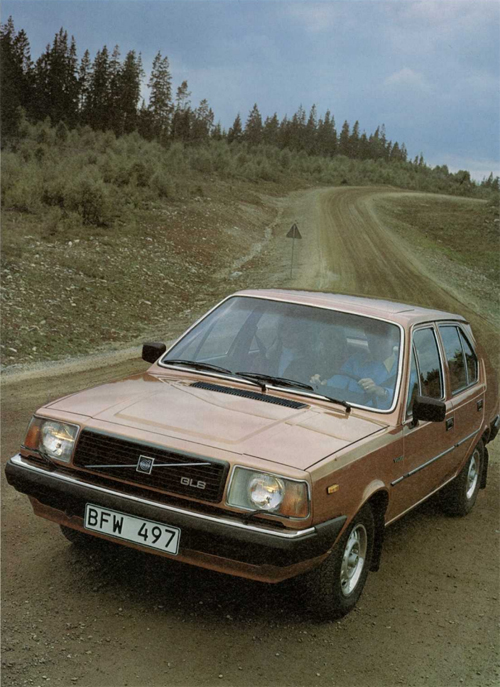

1981 – Volvo 343 DLS and 345 GLS at Volvo Hällered Proving Ground

1981 – Volvo 345 GLS at Volvo Hällered Proving Ground

1981 – Volvo 345 GLS at Volvo Hällered Proving Ground

1981 – Volvo 343 at Volvo Hällered Proving Ground

1981 – Volvo 345 GL at Volvo Hällered Proving Ground

1981 – Volvo 244 GLT at Hällered Proving Ground in Sandhult near Borås Sweden 🇸🇪

(Photo by Glen Percival)

1981 – Volvo Cars Range with 244, 264, 245, 345 and 244 Turbo at Volvo Hällered Proving Ground

1981 – Volvo 264 on Volvo Hällered Proving Ground

1981 – Volvo 264 on Volvo Hällered Proving Ground

1981 – Volvo 264 GLE at Hällered Proving Grounds

1981 – Volvo 240 at Volvo Hällered Proving Ground

1981 – Volvo 244 Turbo with 340 and other 240s at Hällered Proving Ground in Sandhult near Borås Sweden

1981 – Volvo 244 Turbo at Hällered Proving Ground (Photo by Glen Percival)

1981 – Volvo 244 Turbo on Volvo Hällered Proving Ground

1981 – Volvo 244 Turbo on Volvo Hällered Proving Ground

1981 – Volvo 244 Turbo on Volvo Hällered Proving Ground

1981 – Volvo 244 Turbo on Volvo Hällered Proving Ground

1981 – Volvo 244 Turbo on Volvo Hällered Proving Ground with German plates.

1981 – Volvo 264 GLE on Volvo Hällered Proving Grounds.

1981 – Volvo 345 GLS at Volvo Hällered Proving Ground

1981 – Volvo 264 GLE and 245 at Hällered Proving Ground

1981 – Volvo 244 GLT (with BMW) at Hällered Proving Ground

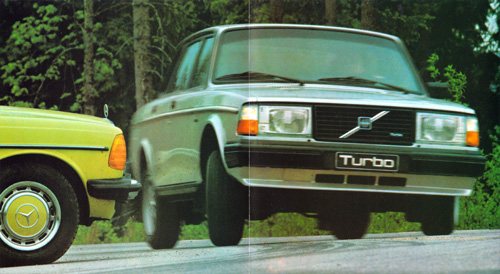

1981 – Volvo 244 Turbo (with Mercedes Benz) at Hällered Proving Ground

1982 – Volvo 760 GLE at Volvo Hällered Proving Ground

1982 – Volvo 760 GLE at Volvo Hällered Proving Ground

1982 – Volvo 345 GL at Volvo Hällered Proving Ground

1982 – Volvo 345 GLS at Volvo Hällered Proving Ground

Behind the Scenes with Volvo 345 GLS at Volvo Hällered Proving Ground in 1982

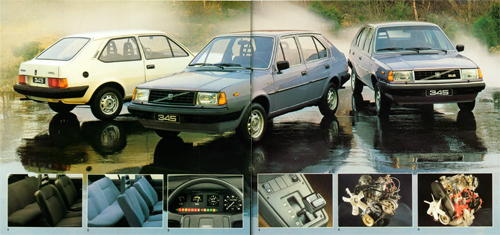

1982 – Volvo 343 DL, 345 GL and 345 GLS at Volvo Hällered Proving Ground

1982 – Volvo 343 DL, 345 DL and 345 GLS at Volvo Hällered Proving Ground.

1982 – Volvo 244 GL at Volvo Hällered Proving Ground

1982 – Making of Volvo 244 GL press photo by Ulf Holmstedt at Volvo Hällered Proving Ground

1982 – Volvo 244 GL at Volvo Hällered Proving Ground

1982 – Volvo 343 och 244 GL at Volvo Hällered Proving Ground

1983 – Volvo LCP2000 at Volvo Hällered Proving Ground

1983 – Volvo LCP2000 at Volvo Hällered Proving Ground

1983 – Volvo LCP2000 at Volvo Hällered Proving Ground

1986 – Volvo 760 GLE and Volvo 240 (from 1985) at Volvo Hällered Proving Grounds.

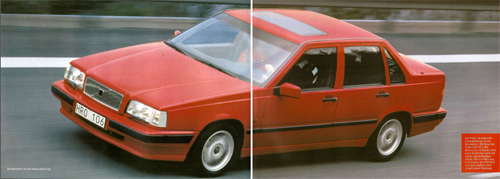

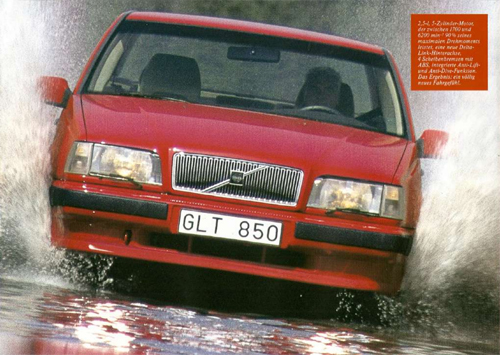

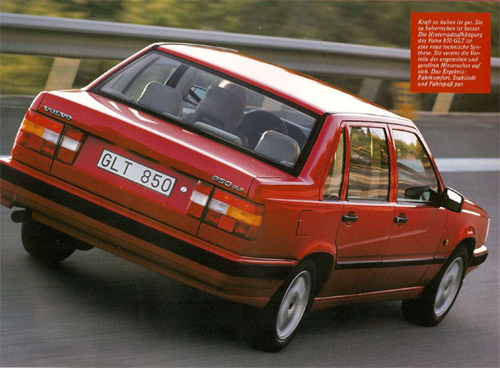

1991 – Volvo 850 on Hällered Proving Grounds.

1991 – Volvo 850 GLT on Hällered Proving Grounds.

1991 – Volvo 850 GLT on Hällered Proving Grounds.

1991 – Volvo 850 on Hällered Proving Grounds

1991 – Volvo 850 GLT on Hällered Proving Grounds.

1991 – Volvo 850 GLT on Volvo Hällered Proving Ground

1991 – Volvo 850 GLT on Volvo Hällered Proving Ground

1991 – Volvo 850 GLT on Volvo Hällered Proving Ground

1991 – Volvo 850 GLT on Volvo Hällered Proving Ground

1992 – Volvo ECC at Volvo Hällered Proving Ground

1992 – Volvo ECC at Volvo Hällered Proving Ground

1992 – Volvo ECC at Volvo Hällered Proving Ground

1992 – Volvo ECC at Volvo Hällered Proving Ground

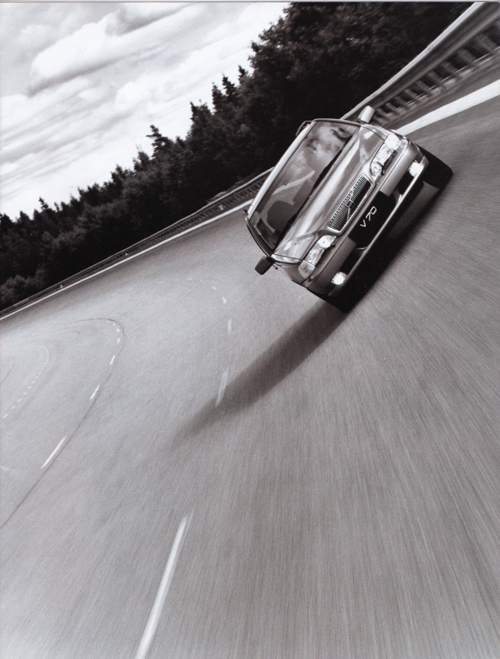

1997 – Volvo V70 at Volvo Hällered Proving Ground

1998 – Volvo S70 at Volvo Hällered Proving Ground

1998 – Volvo S80 T6 at Volvo Hällered Proving Grounds.

1998 – Volvo S80 T6 at Volvo Hällered Proving Grounds.

1998 – Volvo S80 T6 at Volvo Hällered Proving Grounds.

1998 – Volvo S80 T6 at Volvo Hällered Proving Grounds.

1998 – Volvo S80 T6 at Volvo Hällered Proving Grounds.

1998 – Volvo S80 T6 at Volvo Hällered Proving Grounds.

1998 – Volvo S80 T6 at Volvo Hällered Proving Grounds.

1998 – Volvo S80 T6 at Volvo Hällered Proving Grounds.

1998 – Volvo S80 T6 at Volvo Hällered Proving Grounds.

1998 – Volvo S80 T6 at Volvo Hällered Proving Grounds.

1998 – Volvo S80 T6 at Volvo Hällered Proving Grounds.

2003 – Volvo S60 at Volvo Hällered Proving Ground

2006 – Volvo XC90 Sport at Volvo Hällered Proving Ground

2006 – Volvo XC90 Sport at Volvo Hällered Proving Ground

2006 – Volvo XC90 Sport at Volvo Hällered Proving Ground

2006 – Volvo XC90 Sport at Volvo Hällered Proving Ground

2006 – Volvo XC90 Sport at Volvo Hällered Proving Ground

2006 – Volvo V70 Multi-Fuel at Volvo Hällered Proving Ground

2006 – Volvo V70 Multi-Fuel at Volvo Hällered Proving Ground

2006 – Volvo V70 Multi-Fuel at Volvo Hällered Proving Ground

2006 – Volvo V70 Multi-Fuel at Volvo Hällered Proving Ground

2010 – Volvo XC60 at Volvo Hällered Proving Ground

2010 – Volvo XC60 at Volvo Hällered Proving Ground

2010 – Volvo Magasin with Stefan Sällqvist and Volvo S60 at Volvo Hällered Proving Ground

2011 – Volvo C30 Electric at Volvo Hällered Proving Ground

2011 – Volvo C30 Electric at Volvo Hällered Proving Ground

2011 – Volvo C30 Electric at Volvo Hällered Proving Ground

2011 – Volvo C30 Electric at Volvo Hällered Proving Ground

2012 – Volvo S60 Polestar Concept at Volvo Hällered Proving Ground

2012 – Volvo S60 Polestar Concept at Volvo Hällered Proving Ground

2012 – Volvo S60 Polestar Concept at Volvo Hällered Proving Ground

2012 – Volvo S60 Polestar Concept at Volvo Hällered Proving Ground

2012 – Volvo S60 Polestar Concept at Volvo Hällered Proving Ground

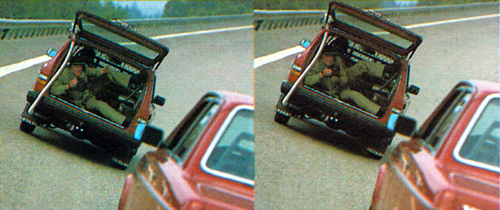

2012 – Safe Road Trains for the Environment – SARTRE road train being tested at Hällered proving ground in Sweden

2012 – Safe Road Trains for the Environment – SARTRE road train being tested at Hällered proving ground in Sweden

2012 – Safe Road Trains for the Environment – SARTRE road train being tested at Hällered proving ground in Sweden

2012 – Volvo V60 at Volvo Hällered Proving Ground.

Intersection Support is a research project that extends auto brake possibilities to also cover intersection situations. Sensors register critical intersection incidents and the car brakes automatically if necessary. The image shows the system being tested system at Volvo Car Corporation’s test track.

2012 – Volvo V60 at Volvo Hällered Proving Ground.

2012 – Volvo V60 at Volvo Hällered Proving Ground.

2016 – Volvo V90 Polis at Volvo Hällered Proving Ground

2016 – Volvo V90 Polis at Volvo Hällered Proving Ground

2016 – Volvo V90 Polis at Volvo Hällered Proving Ground

2020 – Volvo XC90 at Volvo Hällered Proving Ground

2020 – Volvo XC90 at Volvo Hällered Proving Ground

2021 – Volvo C40 Recharge at Volvo Hällered Proving Ground

2021 – Volvo C40 Recharge at Volvo Hällered Proving Ground

2021 – Volvo C40 Recharge at Volvo Hällered Proving Ground

2021 – Volvo C40 Recharge at Volvo Hällered Proving Ground

2021 – Volvo C40 Recharge at Volvo Hällered Proving Ground

2021 – Volvo C40 Recharge at Volvo Hällered Proving Ground

2021 – Volvo C40 Recharge at Volvo Hällered Proving Ground

2021 – Volvo C40 Recharge at Volvo Hällered Proving Ground

2021 – Volvo C40 Recharge at Volvo Hällered Proving Ground

2022 – Volvo C40 Recharge at Volvo Hällered Proving Ground

2022 – Volvo C40 Recharge at Volvo Hällered Proving Ground

2022 – Volvo C40 Recharge at Volvo Hällered Proving Ground

Volvo Hällered Proving Ground is located in Sandhult just north of Borås, Sweden. The facility is owned by Volvo Cars and is an important part of their product development.

The operation takes place 24/7 and a total of about 300 people at Hällered Proving Ground work with setting up test vehicles, conducting test runs, doing laboratory tests and evaluating test results. The facility’s own maintenance organization also provides service and maintenance for the facility.

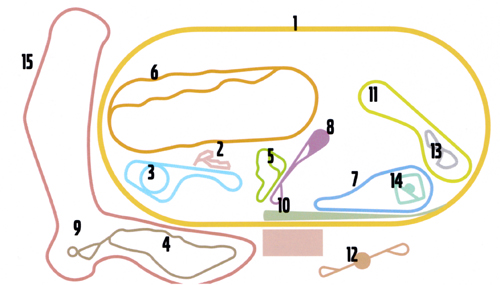

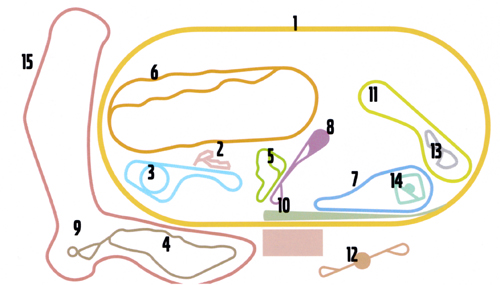

2010 – Volvo Hällered Proving Ground

The 15 test tracks at Hällered Proving Ground are designed to give drivers maximum safety and the highest degree of reliability in test results. Advanced testing that covers a wide range of vehicle attributes is constantly performed at the test tracks. Sustainability, comfort, performance, safety and reliability are functions that are evaluated around the clock by our employees at Hällered. Drive wheels, chassis, steering, active safety features, cooling, suspension, shock absorbers and tires are other examples of systems and components tested here.

In addition to test tracks, the facility also has a number of laboratories where they perform tests and analyzes. Engineers, technicians, mechanics and test drivers employed by Volvo Cars, located on Hällered, perform objective testing and driving. Hällered covers an area of about 700 hectares and is mainly a self-sufficient community. In addition to workshops, test laboratories and test rigs, there are administration buildings with offices, conference rooms, a restaurant and more.

At Volvo Cars’ test track Hällered the car is pushed to its limit. Surrounded by a beautiful forest it is a quiet and peaceful place.

But then the forest opens and the track nicknamed “Car Hell” can be found – Hällered.

This is the place where Volvo cars are made to suffer around the clock in extraordinarily tough conditions. In only a few months the cars are aged as much as during the entire anticipated lifetime of the vehicles in ordinary traffic circumstances.

The test facility at Hällered in Sweden is a veritable “torture chamber” for cars. This is where tomorrow’s components and cars are tested long before production starts. For a lifetime test, a car is driven really hard for 160,000 kilometres within a little less than a year. The equivalent of four complete circuits of the earth.

At the test facility there are 15 different test tracks where everything a Volvo car can be facing up to during its long life time is tested.

2016 – Volvo S90 and V60 on Volvo Hällered Proving Ground

On the main track they bring the cars to their limits at full speed during interminable driving cycles at speeds of over 250 kilometres per hour.

On other tracks driving stability on the road and chassis components are tested with cars driven round tough bends. Annually the test drivers wear out some 2,000 tires.

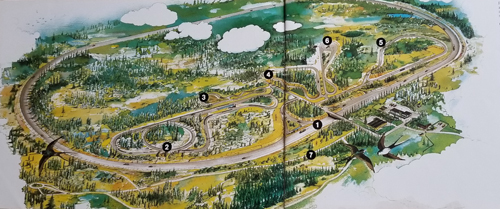

1985 – Volvo Hällered Proving Ground Map

The facility also includes tracks where they test all-wheel driven vehicles over extreme off-road conditions.

Along the 5 kilometres public highway type of track there are different kinds of demanding surfaces just like those to be found on real public highways.

The cascade of salt water on the lifetime track severely tests the bodywork’s rust protection. The suspension and shock absorbers really have their work cut out when the surface is aggressively rough.

Gravel tracks are a Nordic specialty that really challenges road holding qualities.

The car’s active safety system is also tested at the facility. A special rig has been developed just to test the Pedestrian Detection system that should detect pedestrians and apply the brakes in case the driver does not react in time.

The about 75 test drivers who work at the facility play an important role. They are all well trained in advanced driving techniques and each one of them drives about 100,000 kilometres per year as a part of their work. It is their careful work that is the backbone of the whole operation.

In the workshops and service stations at the facility, operations are carried on around the clock all year round. Test cars must be kept going and every hour is expensive. And all the time there are new cars waiting to be driven in the toughest tests.

In 1969, Volvo started to plan this proving ground at Hällered outside Göteborg. The site was 6 million m2 in size and the proving ground was due to be completed in 1972.

The 15 tracks in detail:

1. High Speed Track

The high speed track functions as an endless motorway. It is used to conduct function, reliability, performance and durability tests. The curves are formed like a velodrome and are graded to offer driving that is unaffected by lateral forces at speeds of approximately 200 km/h. The lateral slope on the straightways is 1% and it gradually increases in the curves to 74%. There is a water trench of varying depths adjacent to the track. The high speed track is approximately 6,200 metres long and is divided into four track lanes with a total of 16 meters.

2. Construction Site Track

The construction site track is used for testing the durability of trucks, dumpers and off-road vehicles. The track has a surface that is similar to rough construction sites, hilly gravel pits and refuse tips. The track is approximately 750 metres long and 4 metres wide. There is a loading area adjacent to the track because loadingand unloading is part of some of the testing.

3. Durability Track

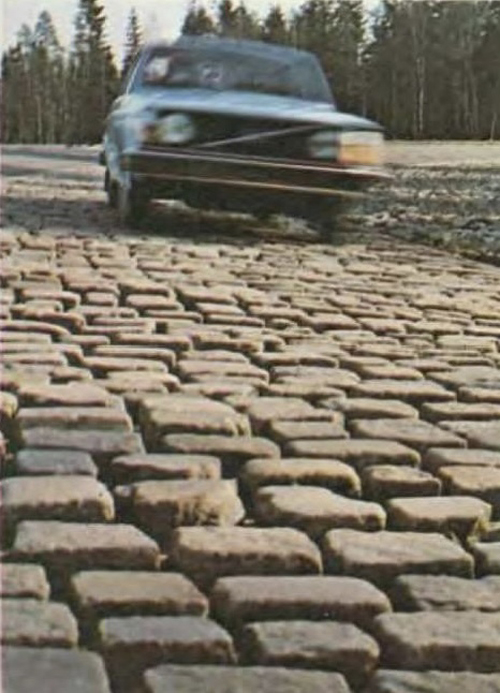

The durability track is used to test the reliability function and durability of, primarily, body and chassis components. It contains various types of “irregularities” that include Belgian cobblestone, grooves, potholes, hollows, bumps as well as trenches with mud and water. The well-defined road surface patterns result in high levels of stress and accelerated wear. This means that testing cnbe conducted in a shorter periods of time and distances. The track is approximately 2,600 metres long, including a circular section of cobblestone.

The surface of the external noise measuring track is similar to continental cobblestones and generates vibrations in a vehicle’s chassis, body and interior. Test drives and analysis are conducted here to prevent squeaks, rattles and scraping noises. The track is circular, making its length af 530 metres infinite.

4. Gravel Track Road

This track is used for durability, reliability and fucntion tests. It is specially prepared with the type of gravel used on roads. The track is approximately 1.5000 meters long and 6 meters wide.

5. Handling Track 1

Handling track 1 is used for testing tyres and reliability as well as for testing a vehicles driving characteristics. The track has S-bends and incorrectly graded hairpin and spiral curves. The entire track can be sprayed with water. Handling track 1 is approximately 850 meters long and 6 meters wide. It contains a 100-meter long and 10-meter wide straightaway and a parallel circuit with an S-bend.

6. Handling Track 2

Handling track 2 is used to test a vehicle’s handling and reliability. The track contains “irregulairities” such as bumpy surfaces, incorrectly graded bends and wheel tracks. One section of the track is divided into car and truck circuits. There is also a dirt-test track adjacent to the truck circuit. The track is approximately 3.100 meters long and 6 meters wide. In one 200-meter section, the track’s width increases to 200 meter.

7. Comfort Track

The comfort track is used to test a vehicle’s comfort characteristics, solidness, function and reliability. The track contains some 20 different types of roads, including “washboard”, a grooved surface, bumps, asphalt repairs in curves and straightaway, gaps between sections of concrete, Vienna cobblestones, etc. The Comfort track is approximately 2,100 meters long and 7 meters wide. It also includes a 3.500 m² asphalt area that is used to test high lateral forces and an “easy” construction track for cars.

8. Skidpad

The Skidpad, which can be sprayed with water, is used for tests involvng strong lateral forces. It consists of a circulair asphalt surface with drainage with two entry tracks. The skid pad is 100 meters in diameter. It has a gradient of 0,5%, with the lowest point at the centre. In applicable cases, it is also used to test range.

9. Slopes

The slopes are used for testing drivelines and driveline installations, brakes and tow bars. Certain slopes are also used for norm testing of brakes, uphill capacity, etc. The gradient of the hills are between 8% and 60%.

10. Low Friction Track and Handling Area

Special tracks have been built for testing brakes on areas of normal asphalt as well as on sections with low-friction surfaces. The Low Friction track is primairly used for testing and developing electronic safety systems. The track has a surface of basalt plates and a system of nozzles to spray water onto the track, which provides to correct degree of friction to meet applicable regulations and legislations. The Low Friction track is 310 meters long an 7 meters wide.

The Handling track is used for tests that requires a great deal of space, for example when testing steering and driving characteristics of both heavy vehicles and cars. The trackis horizontal and its lateral gradient is not more than 1,2% one-directional banking. The surface is paved with normal asphalt with the exception of the right-hand (eastern) side, which is paved with a special noise-generating type of asphalt at a width of 3,5 meters and a lenght of 500 meters. The Handling Area has an overall width of 60 meters and a lenght of 500 meters.

11. Corrosion Track

The Corrosion Track, together with the climate chambers, is used for corrosion testing. The track is 1,950 meters long and 7 meters wide. It is paved with stone chips on a asphalt base and has a system for pouring saltwater over the test vehicles. One section of the Corrosion Track consists of a “salt splash” tunnel that simulates the swirling spray and built-up of dirt that occurs when e.g. driving behind a truck on a wet, salted road in the winter.

12. External Noise Masuring Track

The purpose of this track is to test and measure exterior noise levels and it is used primarily by Volvo Trucks and Buses. The tests are used partly to help develop quieter vehicles and also to ensure compliance with current national and international legal requirements. The track is approximately 1,200 meters long. The entry sections are paved with normal asphalt while the central measuring area is paved witha type of asphalt specified by ISO. The central sections of the track can be heated from underneath to keep them dry in damp or cold weather.

13. Rough Road Track

Among other things, this track is used to test the cars’ AWD system. The track is approximately 1,150 meterslong and consists of sectionsof road gravel and asphalt. There are a number of hills with different degrees of difficulty adjacent to the track for testing cars fitted with All Wheel Drive.

14. City Traffic Course

This track is similar to streets around a square city block and is used by cars and heavy trucks. The testing conducted here simulates turns at street corners and stop-and-go traffic. This puts special strain on the chasis and driveline. There is a hill with a 16% gradient adjacent to the track that is used to test starting on a hill. The City Traffic Course is approximately 650 meters long and has a curve radius of 12 meters.

15. Country Road Track

This track is primarly used to conduct tests of the active safety systems. It is 5,000 meters long. Several of the natural bends and hills are copied from various sections of road in Sweden, the United States and England. The Country Road Trak also offers several different types of surfaces and “irregularities”, suck as American concrete highways, manhole covers and bridge sections that enables to conduct noise tests in and outside of the cars.

(Information from the Volvo Hällered Proving Ground brochure)

Hallered: every petrolhead’s dream

Imagine having 15 different tracks at your disposal, which range from a 6,2 km high-speed oval, to high- and low-speed handling circuits, off-roading areas, gravel and dirt paths as well as cityscapes. Now imagine going there every day.

What I described above is just some of what makes up the Hallered Proving Ground, owned by Volvo Cars, just outside of Gothenburg, Sweden. For a lucky few, this is a reality and not only do they have access to this petrolhead playground but they get paid to visit and drive there daily.

One such person is Christer Aldeby, test driver for Volvo Cars. Aldeby, one of about 90 pilots in the employ of Volvo at this facility, was my host when I recently visited Hallered.

The total count of staff on the premises is roughly 300, including mechanics, engineers, maintenance staff and traffic control.

Allowing journos into the most secret of test areas isn’t usually allowed, but this rare occasion was made possible by Volvo on special request.

Aldeby doesn’t look like your typical Swede: he isn’t tall, have light hair, eyes or skin and when I learn that he was born in Iran his appearance suddenly made a lot more sense.

Unlike many test drivers at other car makers who at some point had racing ambitions Aldeby was once a taxi driver, then a limo chauffeur before eventually making the step up to test drive at Volvo Cars.

He’s fulfilled this role for a decade and from conversations with him during my time at Hallered he has no intention of leaving anytime soon.

Most people think that being a test driver is simply about driving flat out all the time though this isn’t really the case.

At Hallered driving teams work through the night to be able to fulfil the stringent requirements of tests. Over the course of the year each driver at Hallered covers about 100 000 km and that’s just at the proving ground!

Aldeby does however state that one of the engine test procedures is to run a car flat out in top gear around the facility’s high-speed oval track for twenty laps… so that is part of the job, too, just not ALL of the job.

Hallered was opened in 1973 and has since been the heart of the Swedish automaker’s testing arenas. There are other proving grounds, such as the cold weather test facility near Jokkmokk in Lapland, or the one in the US, which is ideal for warm weather work.

Among the various tests conducted within the 700-hectare grounds include life expectancy, reliability, comfort and performance characteristics, and that’s just on the vehicle side.

Any number of tests can be carried out in the laboratories from fuel analysis to hot and cold weather testing of components.

Within the grounds are all manner of labours that a car will endure within its lifecycle, not to mention several dozen that most wouldn’t consider within the scope of normal usage.

Side slopes with “fallen” logs, rock gardens, paved sections with simulated, deep-set manholes, Belgian pave, steep inclines and declines of dirt and tar are all there for test drivers to thump test cars against.

I felt a twinge of sympathy for the car that were travelling in on the day of my tour as Aldeby thumped over the various obstacles, but he assured me that in its 90 000-odd km, all of which were earned at Hallered, it’s seen a LOT worse. Incidentally there wasn’t the slightest creak or squeak to be heard in the cabin.

Not all 90 drivers are allowed to conduct the full spectrum of tests at Hallered. Even though they might ultimately be capable drivers, each needs to obtain specific licences for different levels of test procedures.

With a T1 grading you are only allowed to drive to a maximum 130 km/h within the grounds. Stepping up to T2, which entails a theoretical and driving exam, lifts the speed cap to 250 km/h.

T3 holders are allowed the full speed range and it is these highly skilled men and ladies that are certified to do chassis and handling testing. My driver for the day happens to be T3 accredited.

While most enthusiasts imagine that being a test driver is a glamourous occupation where you fling cars around racetracks al day, the reality is very different.

Aldeby has a 9-to-5 gig, like most others, that requires him to report to a boss every day. Though, if you have to choose from all the places you’d like your office to be, Hallered Proving Ground must be right up there with the best of them.

2008 – Volvo Cars Hällered Test Track (Youtube.com)

2010 – Top Secret Proving Ground: Hällered, Sweden (Youtube.com)

2010 – Hallered Volvo test ground in Sweden – Ground views (Youtube.com)

2019 – My Volvo V70 Drive at Volvo Hällered Proving Ground

In April 2019, I was lucky to visit the Volvo Hällered Proving Ground together with Svenska Volvoklubben. This was the only photo that I could take, outside the complex.

After an introduction on the test track, we were able to join with a new road car the Volvo Hällered Proving Ground. It was a great experience!

More information at media.volvocars.com, carmag.co.za, lukeperkins.com and saabblog.net.

Posts

Posts